With high customer expectations, continuing labor shortages, uncertain carrier capacity, and rising warehousing and shipping costs, it's becoming increasingly difficult to meet customer delivery expectations while preserving order margins.

The warehouse’s floor feels this pinch as e-commerce forces the adoption of different fulfillment models, ongoing market ebbs and flows make it challenging to balance fluctuating demand with resourcing and space, and inflation pushes up the cost-to-serve for each order. The same pressures are felt at the shipping dock, where higher shipping cost per pound and mile, not to mention capacity uncertainty, restricted volumes, and increasing surcharges are eroding already-thin margins.

Against these market and operational headwinds, shippers need to implement scalable and adaptable processes and systems, maximize space and resources, and increase productivity and flexibility to delight their stakeholders and customers.

Predictably and Profitably Achieve the “Perfect Order”

This is where a Fulfillment and Final-Mile Maturity Model can help. It helps companies assess their logistics capabilities and guides them through achieving higher levels of efficiency, integration, and customer satisfaction. It will help to consistently achieve the “perfect order” – the right product from the right place at the right time with the right packaging and carrier service for the right delivery experience. It will enable companies to responsibly grow and expand, achieve faster speed to benefit, increase ROI, and invest (and re-invest) in continuous improvement.

The Fulfillment and Final-Mile Maturity Model is adapted from existing e-commerce, logistics, and warehousing models. It is complementary to those models with a focus on the specific functions needed from the moment an order is received on the warehouse floor to when it leaves the shipping dock, and ultimately ends up on the consumer’s doorstep. It emphasizes the need to integrate and communicate across the enterprise and with partners and customers to reduce friction between individual functions or departments looking to optimize order delivery. It is not intended to be rigid. It’s intended to be fluid and to embrace incremental change and continuous improvement, allowing companies to evolve and grow to meet threats and opportunities.

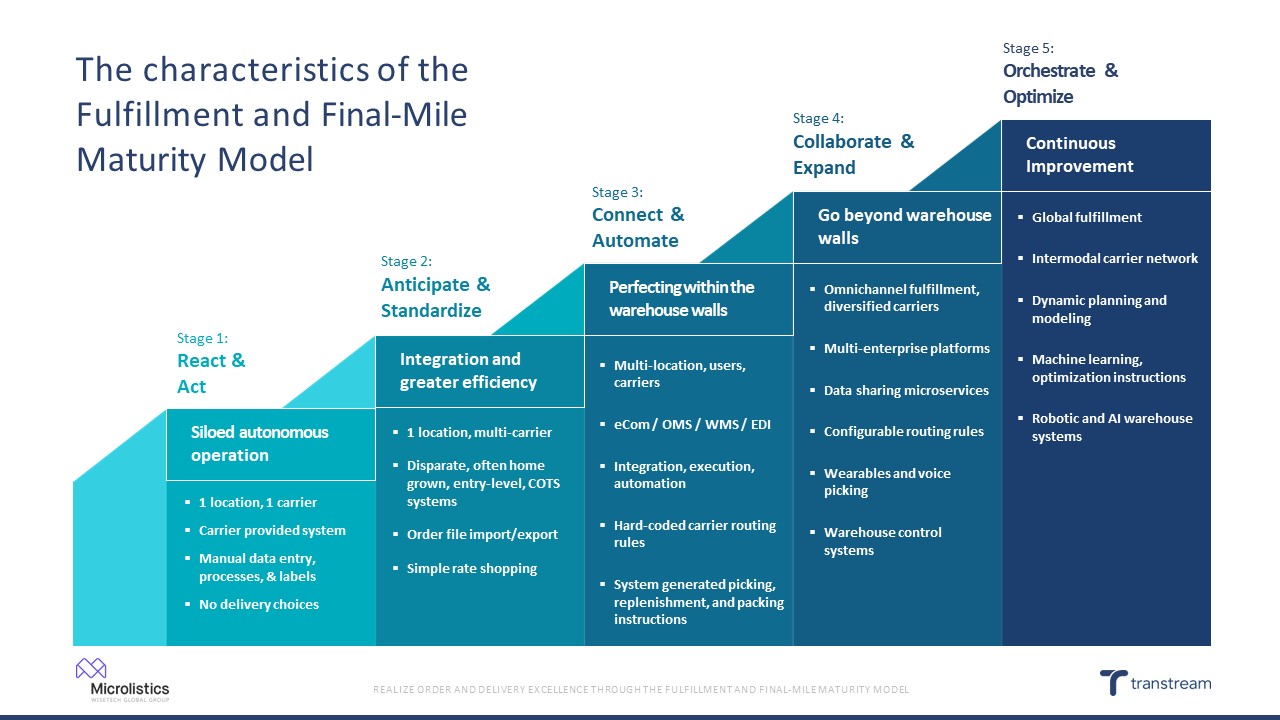

The Five Stages of the Fulfillment and Final-Mile Maturity Model

The maturity model consists of five stages, starting from siloed and manual processes to advanced levels of automation, collaboration, and optimization. The model emphasizes integration, standardization, data sharing, configurable business rules, and the use of technologies like wearables, robotics, and artificial intelligence to achieve continuous improvement and global fulfillment capabilities.

Stage 1 – React & Act to Move Forward from Siloed Autonomous Operations

This is generally the startup phase with a lot of siloed autonomous operations and few, if any, documented processes. Typically, organizations manage through people and exceptions with little information exchanged across the organization. Organizations at this stage need to start identifying where things are breaking down and digitize those functions, begin to improve key processes, and prioritize low-hanging fruit. The focus should be on order speed and error rates, and organizations will begin to see faster, more accurate fulfillment.

On the warehouse floor: Optimize space with advanced racking systems and specific pick faces that support particular markets, verticals, or customer types to streamline activities in the facility and reduce labor cost.

At the shipping dock: Expand carrier choices to regional and local carriers with multi-carrier management for cost-effective rating and routing decisions and consistently meeting customer delivery expectations.

Stage 2 – Anticipate & Standardize for Better Integration and Greater Efficiencies

This is where organizations can look to improve integration and drive efficiency. At this stage, organizations will start to feel the pain of not having processes documented, so begin to document manual operations. They are also looking to improve margins by shopping for least-cost suppliers or carriers. There may be a focus on inventory reduction and aligning demand with inventory on hand, but they may still see little internal coordination between departments.

On the warehouse floor: Maximize resources and inventory with system-driven tasks via handheld devices and triggered inventory replenishment to improve resource utilization and inventory turns.

At the shipping dock: Continue to evaluate carriers and expand carrier choices for efficiencies and additional market coverage, rate shop on optimized service instead of cost, and batch print labels to reduce manual entry and errors for a higher percentage of on-time, on-budget deliveries.

Stage 3 – Connect & Automate to Perfect Within the Walls of your Organization

Here organizations are becoming fully integrated enterprises with a focus on process automation and internal integration, developing comprehensive internal communications and process documentation, and enhancing inventory demand planning and fully connecting with all sales channels. With a focus on the full order lifecycle, organizations will begin to see more efficient cycle times, reduced cost-to-serve, and fewer un-fulfilled orders and returns.

On the warehouse floor: Automate picking and packing with instructions that account for resource steps and packing while picking to ensure the highest cost mitigation and customer satisfaction.

At the shipping dock: Shift control to logistics managers and systems with configurable instructions that account for carrier performance, and all post-shipment charges to improve time-in-transit and cost containment.

Stage 4 – Collaborate & Expand to Go Beyond Your Operational Walls

At this stage, organization are becoming extended enterprises by integrating across boundaries with a focus on becoming a better vendor to their customers and a better customer to their suppliers and carriers to move towards supply chain cooperation versus supply chain competition.

On the warehouse floor: Build supply chain resiliency and redundancy into your operations through multiple inventory sources and inventory minimums and maximums that will keep goods moving consistently and swiftly through the warehouse, maximize sell-through rate, and reduce inventory carrying costs.

At the shipping dock: Ship orders from an endless aisle that can include DCs, storefronts, upstream suppliers, and 3PL partners to eliminate stock outs. Become a better carrier partner by managing to carrier agreements and cartonizing shipments to maximize allotted volume.

Stage 5 – Orchestrate & Optimize to Drive Innovation and Continuous Improvement

Here organizations are investing increased ROI into continuous improvement, adapting to threats and opportunities, and innovating with leading edge technologies to drive competitive advantage, incremental market-share gains, and new market penetration.

On the warehouse floor: Augment human performance with vision and voice picking and pick to light, and warehouse infrastructure with automated conveyance systems, automated guided vehicles, and autonomous motor vehicles to realize the workforce and warehouse of the future.

At the shipping dock: Take advantage of sophisticated shipping techniques like zone skipping and consolidation, international drop-shipping, and delivering from in-transit inventory to turn shipping into a competitive advantage.

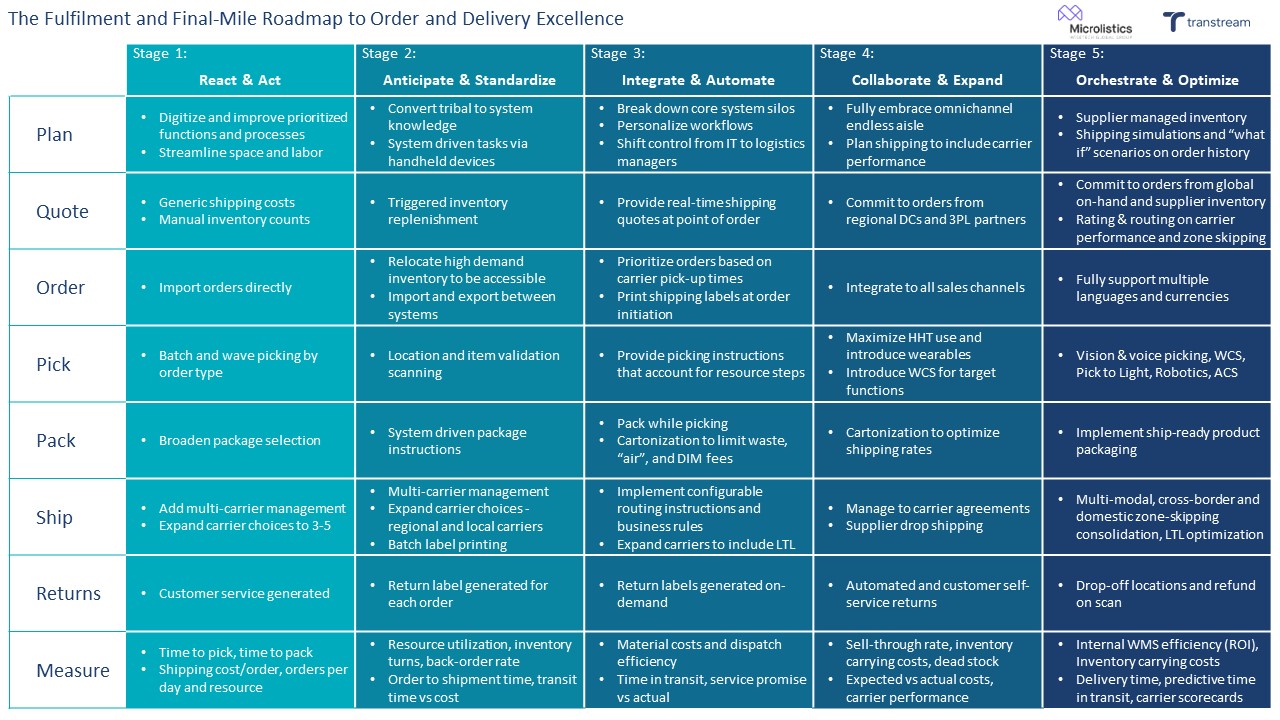

Build Your Own Roadmap

Every organization is different and at different stages of maturity. In the below chart, fulfillment and final-mile functions are broken out, with activities for each to move through the maturity model. Use this sample to customize your own roadmap to achieving order and delivery excellence.

Sample tactical roadmap by function aligned to the Fulfillment and Final-Mile Maturity Model

Leveraging the Fulfillment and Final-Mile Maturity Model allows companies to implement scalable, flexible processes and systems to drive improved accuracy and efficiency, maximizing space and resources while preserving margins and delighting customers; increase productivity and flexibility to adapt to market, business, and operational threats, opportunities, and innovations; and realize greater scalability and profitability to invest in and capitalize on evolutionary growth, improvement, and maturity.

Mark Picarello is Managing Director, Pierbridge, part of the WiseTech Global Group.

This article originally appeared in the September/October, 2023 issue of PARCEL.