The decision of relying on labor over automation has become a critical “fork in the road” decision for many organizations. In today’s warehouse and order picking operations especially, the need for efficiency is beyond critical… it’s likely about the life and death of your operations.

Sounds dire? Well yes it really is. Think about the conditions and state of business that exists today that every organization is competing against in one way, shape or form.

A Global Economy. Let’s start with competing with companies and organizations which pay pennies on the dollar for labor. Granted the price of labor has increased in many lower cost areas, but it’s still an advantage. Plus how many times do we see one region or area open up with cheap labor and then a number of years later another one, and another one… The expression working smarter, not harder was invented for this solution.

Cost of Labor. You don’t have to look too far to see that organizations will be paying higher costs for their labor even if they keep payroll close to flat. Let’s only focus on the healthcare increases every organization has seen and will see in the very near future. Forecasts of labor costs increasing dramatically are in the headlines every day.

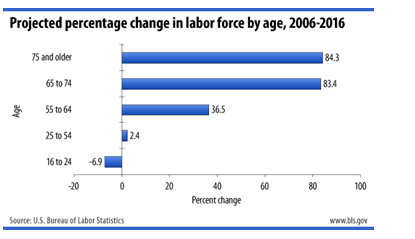

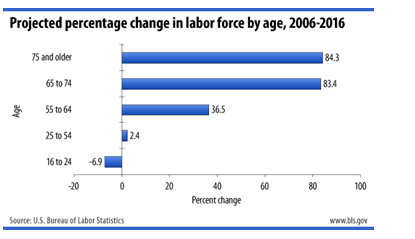

Lack of Workforce. The graying or “silver tsunami” workforce in the US is just starting to impact. The number of U.S. workers between the ages 55 and 64 will grow 51% to 25 million by 2012. At the same time, the number of workers between ages 35 and 44 is expected to shrink by 7%. (Wall Street Journal, Sept 20, 2005). Throw in a workforce which is over 30% obese and finding cheap fresh labor will get tougher than ever.

So if labor (sneakers) will become more expensive, harder to find and less able to perform hard physical work it might be time to find alternatives which use less labor and requires less physical effort (steel and software).

Smarter not Harder. We are back to finding ways to improve the work environment and most importantly provide a return on investment (ROI). Every company needs to turn a profit and return to its investors and principles. Implementing automation is no different; it’s a smart business decision. The only open question is how much and how fast. Honestly, the numbers will dictate this. An investment needs to be smart and provide a nine month to 36 month ROI. The calculations need to be honest and not hedging, hedging and hedging some more till absurd.

Basic ROI calculations need to factor in space savings, energy reductions, labor savings, reduced taxes, reduced training and personnel costs and the benefits of using automation which usually means less errors, increased customer satisfaction, customer retention and additional sales, extended cut-off times and others. The other major element not often calculated is the opportunity value.

By opportunity value we mean the benefits (in a dollar amount) an organization will benefit by utilizing the reclaimed resources provided by automation that otherwise would likely never be done. This often means expanding your product lines or creating new service offerings which both generate revenue.

Likewise, look at your automation ROI project(s) as a whole rather than phases. Often phases are created due to arbitrary lines or resource restrictions not financial practicality. It would be like calling phase one of building a new facility acquiring all materials and phase two construction. Well, there simply isn’t any way this phase one would ever generate an ROI and by many organizations stops phase two dead. So look at the entirety and then figure out phases.

Ed Romaine is CMO - VP Marketing, Integrated Systems Design (ISD) - Andersen Material Handling

Sounds dire? Well yes it really is. Think about the conditions and state of business that exists today that every organization is competing against in one way, shape or form.

A Global Economy. Let’s start with competing with companies and organizations which pay pennies on the dollar for labor. Granted the price of labor has increased in many lower cost areas, but it’s still an advantage. Plus how many times do we see one region or area open up with cheap labor and then a number of years later another one, and another one… The expression working smarter, not harder was invented for this solution.

Cost of Labor. You don’t have to look too far to see that organizations will be paying higher costs for their labor even if they keep payroll close to flat. Let’s only focus on the healthcare increases every organization has seen and will see in the very near future. Forecasts of labor costs increasing dramatically are in the headlines every day.

Lack of Workforce. The graying or “silver tsunami” workforce in the US is just starting to impact. The number of U.S. workers between the ages 55 and 64 will grow 51% to 25 million by 2012. At the same time, the number of workers between ages 35 and 44 is expected to shrink by 7%. (Wall Street Journal, Sept 20, 2005). Throw in a workforce which is over 30% obese and finding cheap fresh labor will get tougher than ever.

So if labor (sneakers) will become more expensive, harder to find and less able to perform hard physical work it might be time to find alternatives which use less labor and requires less physical effort (steel and software).

Smarter not Harder. We are back to finding ways to improve the work environment and most importantly provide a return on investment (ROI). Every company needs to turn a profit and return to its investors and principles. Implementing automation is no different; it’s a smart business decision. The only open question is how much and how fast. Honestly, the numbers will dictate this. An investment needs to be smart and provide a nine month to 36 month ROI. The calculations need to be honest and not hedging, hedging and hedging some more till absurd.

Basic ROI calculations need to factor in space savings, energy reductions, labor savings, reduced taxes, reduced training and personnel costs and the benefits of using automation which usually means less errors, increased customer satisfaction, customer retention and additional sales, extended cut-off times and others. The other major element not often calculated is the opportunity value.

By opportunity value we mean the benefits (in a dollar amount) an organization will benefit by utilizing the reclaimed resources provided by automation that otherwise would likely never be done. This often means expanding your product lines or creating new service offerings which both generate revenue.

Likewise, look at your automation ROI project(s) as a whole rather than phases. Often phases are created due to arbitrary lines or resource restrictions not financial practicality. It would be like calling phase one of building a new facility acquiring all materials and phase two construction. Well, there simply isn’t any way this phase one would ever generate an ROI and by many organizations stops phase two dead. So look at the entirety and then figure out phases.

Ed Romaine is CMO - VP Marketing, Integrated Systems Design (ISD) - Andersen Material Handling