Right out of Henry Ford’s production line, the idea of bringing items to the person rather than having them walk and search for the items sounds not only logical, but proved successful in 1913 when Ford changed the world. Yet here we are almost 100 years later and it’s taken until the last few years for this concept to gain support, in theory, and now slowly in practice.

The term and practice of “Goods to Man/Person” order picking has been gaining momentum over the last few years in North America. Ironically the phrase has been used in Europe for over a decade. Likewise, in the states we modify it to be politically correct “Person” rather than “Man”… well because we’ve been trained to know better ;-)

So Henry Ford proved bringing items to the person and eliminating the operators walk time was very efficient. In fact, it allowed him to reduce the cost of a Model T by 2/3 and increase workers’ pay by almost 100% (up to $5 a day). The Goods to Person process was clearly a winner. In the subsequent decades, many organizations have adopted various forms of Goods to Person, but often in specific markets and for niche portions of their inventory.

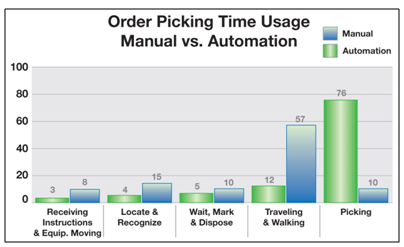

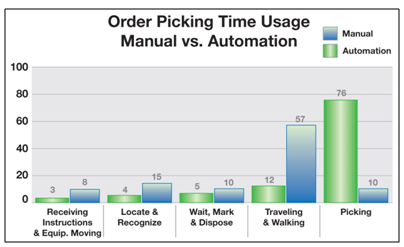

When you look at an order picker’s time study, it’s clear that an operator can eliminate 55% of their wasted time walking and searching and increase actual picking time by 66% with items being brought to the operator. The magnitude of the numbers and success is dramatic.

The term and practice of “Goods to Man/Person” order picking has been gaining momentum over the last few years in North America. Ironically the phrase has been used in Europe for over a decade. Likewise, in the states we modify it to be politically correct “Person” rather than “Man”… well because we’ve been trained to know better ;-)

So Henry Ford proved bringing items to the person and eliminating the operators walk time was very efficient. In fact, it allowed him to reduce the cost of a Model T by 2/3 and increase workers’ pay by almost 100% (up to $5 a day). The Goods to Person process was clearly a winner. In the subsequent decades, many organizations have adopted various forms of Goods to Person, but often in specific markets and for niche portions of their inventory.

When you look at an order picker’s time study, it’s clear that an operator can eliminate 55% of their wasted time walking and searching and increase actual picking time by 66% with items being brought to the operator. The magnitude of the numbers and success is dramatic.

Know Yourself

So 100 years later after Henry Ford proved the concept that operators function at higher levels by bringing the items to them, we have a myriad of technologies, processes and systems designed to do exactly that. The key to success is:

So 100 years later after Henry Ford proved the concept that operators function at higher levels by bringing the items to them, we have a myriad of technologies, processes and systems designed to do exactly that. The key to success is:

1. Understanding your business model and its implications to warehousing and order picking.

2. The nature of your inventory (size, velocity, change, order characteristics and traits).

3. Your facility and labor facts and variables.

4. What is the requisite Return on Investment (ROI) required to make principles and shareholders happy.

2. The nature of your inventory (size, velocity, change, order characteristics and traits).

3. Your facility and labor facts and variables.

4. What is the requisite Return on Investment (ROI) required to make principles and shareholders happy.

I’ve over simplified my four steps and realize that it can take quite a bit of work to gather the proper data, but it’s vital to know who you are, what you do and what you will be doing in order to design and implement the best solution. Keep in mind, there are many third party organizations such as integrators, consultants and manufacturers who will be happy to give you their opinions and perspective (another topic for a future article).

Once you know “yourself” you can create a plan to implement Goods to Person. There is a wide selection of systems available and the key thing to realize is that every technology does some things great, other things pretty darn well and then others not so much.

Likely you will have multiple zones are areas each defined by the type of item to be picked (split case or eaches, case or pallet) and each area’s velocity (how fast inventory moves through zone). A zone is often comprised of one primary technology integrated with conveyor or carts. Most importantly, a facility will usually require multiple technologies (automated and manual) to create a perfect flow and balance.

The Technology & Equipment Selection

The million dollar question is what will provide you with the best results, with the least amount of risk and hit the ROI number you need to hit and NEVER fall in love with a technology. Falling in love with a type of equipment is often the kiss of death.

The million dollar question is what will provide you with the best results, with the least amount of risk and hit the ROI number you need to hit and NEVER fall in love with a technology. Falling in love with a type of equipment is often the kiss of death.

Always balance risk vs. reward on a zone by zone basis, but at the end of the 100 year anniversary of Henry ford’s production line, and proving items to person is more efficient than walking to them, look and evaluate your order picking requirements.

Ed Romaine is the CMO-VP Marketing for Integrated Systems Design - ISD, which provides consulting and integration of cost effective automated pick, pack and shipping systems for warehouses, distribution centers and manufacturers. He can be reached at edromaine@isddd.com, or (215) 512-431-4524 or visit our website at: www.ISDDD.com.

Ed Romaine is the CMO-VP Marketing for Integrated Systems Design - ISD, which provides consulting and integration of cost effective automated pick, pack and shipping systems for warehouses, distribution centers and manufacturers. He can be reached at edromaine@isddd.com, or (215) 512-431-4524 or visit our website at: www.ISDDD.com.