Warehouse Execution Software (WES) has gained in popularity and sophistication in recent years due to its ability to create efficiencies, solve specific user business requirements, and its cost effectiveness.

WES has progressed from concept to “must have” in a relatively fast time. To level set this article, most warehouses and distribution centers (DC) have had multiple layers of software. Enterprise Resource Planning (ERP) is the business logic and applications on top. The Warehouse Management Software (WMS) is layered below to primarily manage everything within the four walls. The bottom level was Warehouse Control Software (WCS). This level focused on optimizing the different zones’ or areas’ technologies. This hierarchy allowed facilities to manage the operations but created islands of automation. This also led to an inability to optimize the entire facility’s equipment and labor in real time.

The line between where WMS leaves off and WCS starts has, over time, become blurred. The cost of development within a WMS being significantly greater than the cost to create similar functionality within WCS, plus the requirement to manage multiple “islands” of automation, has resulted in the WES being born. An optimized WCS with many of the features previously found in WMS systems is designed to orchestrate the entire operation to perform as efficiently and effectively as possible. Knowing that no order leaves the building until the last piece is picked and packed, the WES makes sure each area is operating to mitigate peaks and valley activities otherwise found during the course of a day, an hour, a zone, or work area.

Recycled Code Is Problematic

Many software companies will sell their first system and write the code. Then they sell another system, and they modify the first system to meet the second project’s needs. This continues job after job. You wind up with similar, but “totally different” systems that are very, very difficult to maintain.

If the original programmer is no longer available, support becomes increasingly difficult. Factor in variations, deviations, new drivers, updates, and equipment that the original programmers never dreamed of, and you can have an awful lot of code, often referred to as bloat or spaghetti code. These deficiencies will manifest in a lack of performance, crashes, memory leaks, and overall complexity to maintain and update.

Modularity, Configurability, and Original Code

Leading WES providers today have an advantage of being able to create software from scratch using new tools and best practices. Building on a clean and concise code, highly configurable modules are created to meet every organization’s operational requirements. This creates a flexible and cost-effective solution for organizations.

Likewise, the code for every project is compiled from its original state… every time. This eliminates using variations from previous versions and their inherent (and hidden) problems.

Each module can be operated independently and communicates to the other modules. So, if you are adding or upgrading modules or total system functionality, it does not impact the other modules. This reduces the WES system’s acquisition cost while allowing future functionality as the business case requires it. This methodology also reduces implementation time and maintenance requirements without sacrificing future needs. The configurability allows many minor changes that formerly were change orders to be configured by the user at no cost.

Emulation or Running the System Before Installation

You will also find emulators built into leading WES software offerings. A software emulator interfaces in the exact same manner as the external devices with which the WES communicates (such as PLCs, scanners, robotic controllers, and host systems).

What this allows software providers to do is much more extensive testing of the WES, pre-installation. In addition, the WES and its configured hardware can be tested at many times the rate required. This helps detect some long-term issues, such as database creep, which is when the database is constantly growing until it eventually chews up all the disk space in the system and crashes or memory leaks. These, and other issues, don't occur during the startup or warranty period; they occur months or years later and are devastating.

The easiest sign that your software system is not performing properly is the need to shut down and reboot over the weekend to gain performance and keep the system running properly. The use of clean code and emulators would have detected and eliminated these issues.

Besides performance, integrated emulators minimize installation time and on-site coding. Nothing is worse than having a cafeteria or conference room full of programmers making changes to your software while in your facility. Emulators help assure the system is properly configured prior to getting on site, expedites going live, and ensures meeting current and future growth requirements.

Best part of having the emulators is you can set it up on a test box and make changes to your system, run it through the emulator, and see what the impact is before you go live. This helps organizations plan and test future scenarios before they occur.

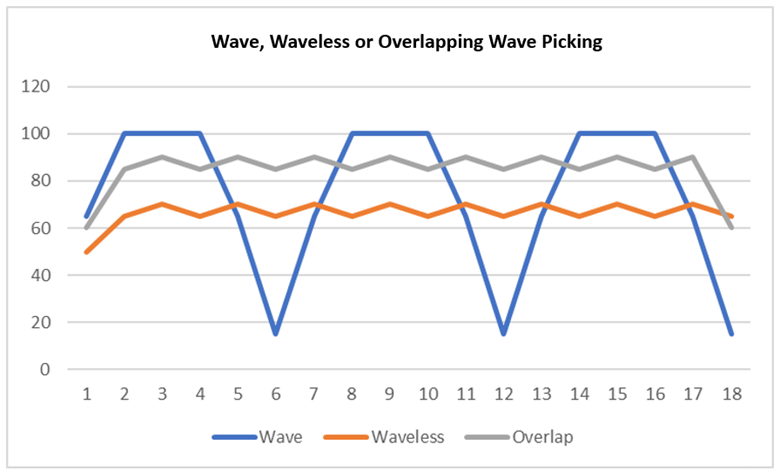

To Pick by Wave, Waveless, or Overlapping Waves

Historically, the WMS sent waves (large batches of orders once or twice per shift). WES introduced the concept several years ago called waveless order picking. Waveless picking helps build more efficient orders and increase picking speeds because there are more orders to pick and optimize from. This was critical to meet several hour- and same-day shipping requirements.

Today’s WES offers a third concept, a hybrid called Overlapping Waves. Using overlapping waves utilizes waveless picking to begin with for maximum efficiency. But towards the end of the wave when it becomes less efficient, overlapping waves are automatically introduced to increase picking efficiencies and flatten out the peaks and valleys.

Looking at the chart, wave picking (blue) illustrates the periods of high productivity, but it also has valleys of low picking productivity as the wave is completed. The waveless picking (orange) evens out the peaks and valleys but provides a lower total throughput. Overlapping waves (grey) illustrates how this hybrid keeps productivity at the higher level of performance than just wave picking.

Let’s say you have 30 lanes in your system. WES uses wave picking for the first wave for 15 lanes, and then when the wave gets about halfway through, it will start kicking in the next wave to the next 15 lanes. Overlapping waves allow the first wave to reach its peak and as it begins to become less productive, the system introduces the second wave. This keeps the entire system at a high level of productivity longer and reduces labor and improves equipment utilization.

Each of the three wave processes work exceptionally well for specific businesses, applications, and order profiles. The key is to have all three available to you when selecting your WES software, so your labor and equipment are optimized.

Freedom of Choice

The ability to use whichever and whatever type of hardware in your organization sounds like a commonsense decision when selecting WES software. Many leading providers of WES software are hardware agnostic, but not all. If they are partially or fully owned by a hardware company, this can lock you into their hardware solutions for the life of your system.

Being hardware agnostic starts with being able to run on various platforms ranging from Microsoft, Unix, Oracle, SAP, etc. This is easily achieved if the WES is written in Java. Being able to select hardware vendors today and in the future due to changes in the market, pricing, reliability, scheduling, and functionality allows organizations to choose their own destiny as business requirements change.

System Configuration Tools

Leading WES systems utilize rapid configuration tools to create your system. There are a number of different ways WES companies perform this, but systems that utilize a Visio type of drag and drop configurability and functionality work very well. By dragging and dropping different hardware system elements such as conveyor, diverts, PLCs, etc. to design your system, it intelligently guides you to the correct parameters. The emulators will act like the PLCs and communicate to your designed system to ensure accuracy and performance levels.

This type of a WES will allow you to change parameters quickly and easily to set conditional and route directives, destinations, settings, scanners and barcode formats, etc. without requiring new coding or programming. These WES systems convert what was always a costly and time-consuming change order to a simple parameter change. Likewise, when the system design is complete and the emulated performance is above parameters, the system will create the system’s “clean code.”

Flexible and Friendly Host Integration

Since WES is layered into an existing infrastructure, its vital that it can integrate to the host quickly and easily regardless of the system. This is done today by simply requesting the host’s output and having the ability to conform to this format. This eliminates host software programming costs and eliminates installation time, complexity, and costs.

Open API and Web-Enabled

Another good feature for a WES to support is an open API for its UI. This allows organizations to incorporate screens that look like your existing system. Custom design screens and incorporating your own branding and logos on the UI are simple to do. Likewise, having the WES UI being web-based allows any mobile computing device that runs Google Chrome to run the WES UI, and application is a must-have. This translates to easier management, deployment, and usage. It also frees management from being tied to a PC terminal and free to roam the DC while still having the data at their fingertips.

So, understanding how WES best practices have evolved over the last few years is often eye-opening. More than ever, organizations are empowered to do as much or as little as they would like to optimize their performance without the risk, cost, and time historically associated with having your operations run the way you want them to.

Ed Romaine is VP of Marketing and Business Development for Conveyco. He can be reached at eromaine@conveyco.com or 215.512.2613.

This article originally appeared in the January/February 2021 issue of PARCEL.