The challenges of 2020 so far, as the world battles the global pandemic of COVID-19, have been unprecedented. The past few years have offered many challenges for logistics professionals, such as increased shipping rates and trade agreement uncertainty, but 2020 was projected to offer new opportunities to the growing supply chain ecosystem. One of those opportunities was small parcel shipping driven by e-commerce. COVID-19 has certainly brought about challenges that make previous obstacles look like child’s play, but there is still much opportunity to be had within this sphere.

According to Pitney Bowes’ Parcel Shipping Index, parcel shipping reached a volume of 87 billion over the 12 months ending October 2019. Moving forward, parcel shipping is expected to reach a volume of 200 billion parcels by 2025, with China (51 billion parcels) and the US (13 billion parcels) leading that volume. This translates to $317B in parcel revenue in 2018, and that’s only for the 13 countries studied! Global parcel revenue may be approaching $400B, with per capita small parcel shipping rising from 12 parcels per person in 2014 to 23 per person in 2018.

With this growth, the small parcel supply chain is getting more complicated. Reducing days in transit is a critical goal for retailers, merchants, and third-party logistics firms (3PLs). Beyond that, managing the people part of shipping grows more complex as more is asked of employees by the day. Operationally, allocating shipping costs by customer, department, project, order, SKU, and other categories is becoming more and more difficult. This is all in a context of demand for free shipping from customers. According to a survey by a large internet retailer in 2016, free shipping was important to over 99% of responders. Sellers are meeting this demand for free shipping in multiple ways, including diversifying to other platforms, adding private label products to their portfolios, selling with Amazon, and using additional fulfillment methods.

A Changing Landscape

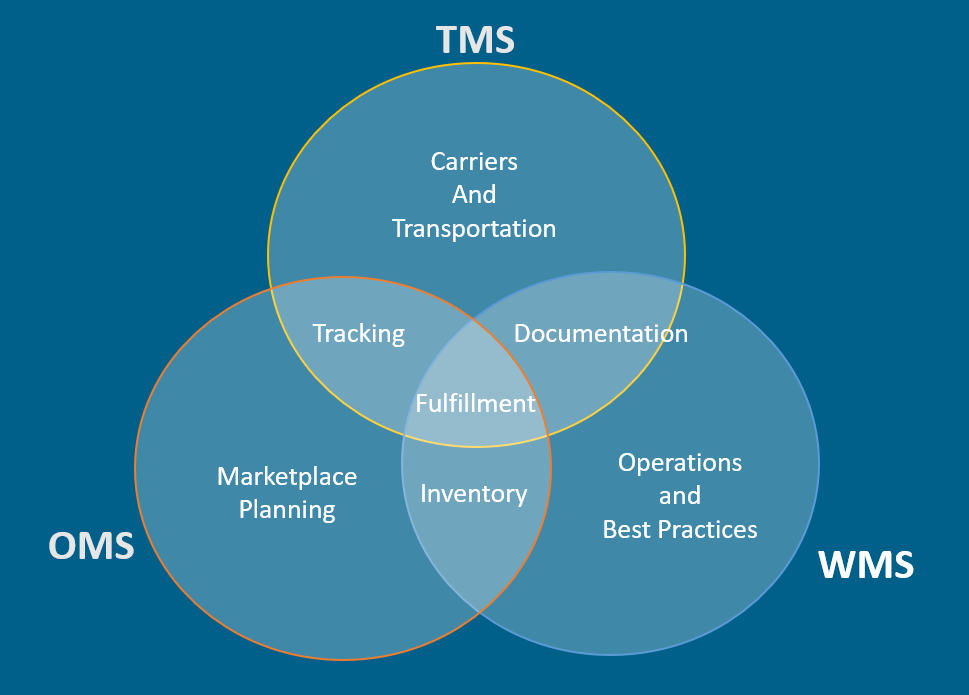

3PL warehouses will need to evolve to operate in this evolving sector, and technology platforms can assist in that evolution. These platforms fall into three broad categories: Order Management Systems (OMS), Warehouse Management Systems (WMS), and Transportation Management Systems (TMS).

OMS manage the order lifecycle. They are usually connected to the front end of the business (website, point-of-sale, etc.) so they can accept orders and route them to the appropriate warehouse.

WMS are the core operating system for warehouses. The WMS allows for fulfillment efficiency by automating the inventory lifecycle, such as assigning pick tickets billing processes and capturing real-time information from the time an order is received into the warehouse until it has been shipped.

TMS manage the freight and carriers once an item is ready to be shipped. Many can “rate shop” amongst carriers to deliver the lowest shipping rate to users, provide best-way routing, control bookings and tenders, and track and trace packages while en route to their destination.

Certain features of these systems can overlap, as shown by the graphic below:

It’s important to understand your needs when evaluating one or more of these types of systems. Vendors who sell on multiple marketplaces, ship from multiple locations, and require order processing logic will need an OMS. Shippers who want to reduce shipping cost and time, require shipment tracking and visibility, and need scalable shipping solutions will need a TMS.

Warehouses who manage inventory, have fulfillment errors or issues, and need to control fulfillment costs will need a WMS. It is important to remember the difference between warehouse management and inventory management as well. Inventory management covers macro-level inventory levels, forecasting and ordering, COGS and profitability analysis, inventory data and inventory utilization across all warehouses. Warehouse management improves operations, drives best practices, manages complexity, provides inventory detail, and services as a single source of inventory truth within the four walls of the warehouse.

Savvy companies will focus on one of these as their “core system” and “bolt-on” others to create a comprehensive suite. It is best to pick a core system that overlaps with the other two functions and provides easy integration points. Investing in technology that offers automated programming interfaces (APIs) will allow your business to create connections to platforms without standard integrations to create a seamless technology experience. Furthermore, users can leverage APIs to layer on value-added technology services like automated billing and reporting that can prevent warehouses from being commoditized as a pure logistics provider. When integrated effectively, OMS, TMS, and WMS can provide a seamless experience for users that streamlines operations and provides the foundation for growth.

In the context of a parcel management strategy, these three types of systems can work together to create dynamic workflows to navigate an increasingly complex supply chain ecosystem. Logistics professionals can enforce a wide range of compliance and SLA requirements, increasing the quantity and quality of carrier and supply chain relationships. This creates a variety of ways that vendors, shippers, and warehouses can generate ROI and keep up with the demands of their customers across the globe!

David Miller is General Manager of Platform Services at 3PL Central, the leading Warehouse Management System (WMS) software platform for Third-party Warehouses. In this role David oversees partner relationships, integrations, and external connectivity capabilities. With two decades of experience in the logistics technology space, David also contributes to company and product strategy.

This article originally appeared in the May/June, 2020 issue of PARCEL.