A couple of years ago, Cascade Orthopedic Supply was facing a challenge: once UPS and FedEx implemented dimensional-based (DIM) pricing, what was the best way to deal with the rising shipping costs that almost inevitably resulted?

If you’re a reader of PARCEL, you understand the concept of DIM pricing. The parcel carriers multiply a package’s length, width, and height, and then divide that number by a dimensional divisor (now 139, but was 166 when Cascade started its search). The shipper is then charged the higher of the actual weight or the dimensional weight. In other words, the higher the dimensional divisor is, the less of an impact it will have on costs. Conversely, the lower the divisor is, the greater the impact.

Cascade was no different when it came to feeling the effects of these changes. As an organization that ships, on average, half a million packages a year (with just a little under 10% of those shipments designated as irregularly shaped), it was crucial that the company take steps to combat this change. Its president, Jeff Collins, explains, “The switch by major carriers to a dimension-based pricing model made managing dimensional data a critical – and inevitable – step in taking back control of shipping costs. The integration of dimensioning is a significant investment, requiring research, new costs, and a rethinking of our processes. We saw opportunity as well as cost: to optimize warehouse space and pick/pack operations, to give customers shipping costs in real time, and to enter a new era of efficiency and control.”

The change in DIM pricing did indeed present these opportunities, but it was also a challenge to find the right solution that would allow these opportunities to be realized. So, armed with their checklist of problems (growing and unpredictable shipping costs; the inability to accurately quote shipping costs to customers at time of purchase; no ability to audit shipping invoices for overcharging; and difficulty in managing irregular-shaped items), Cascade executives set out to find the perfect partner for a solution.

One thing that is critical to understand, Collins shares, was that the company’s goal was two-fold. “More than simply patching individual issues, we wanted to implement sweeping, integrated efficiencies that would create a new standard for ‘best practice.’ Our goal: to raise the bar in speed, economy, and quality in every aspect of how shipping touches our business – from first contact with a customer, through the sales and fulfillment process, and ultimately to our bottom line – yielding service, competitive, and revenue advantages.”

The Process

Cascade had evaluated established, competitive products over the years, but the technology seemed very outdated in light of the fact that major advances had been made in 3D scanning (which, as Collins notes, is now available on anyone’s iPhone). And the cost seemed quite high compared to the quality of the technology available.

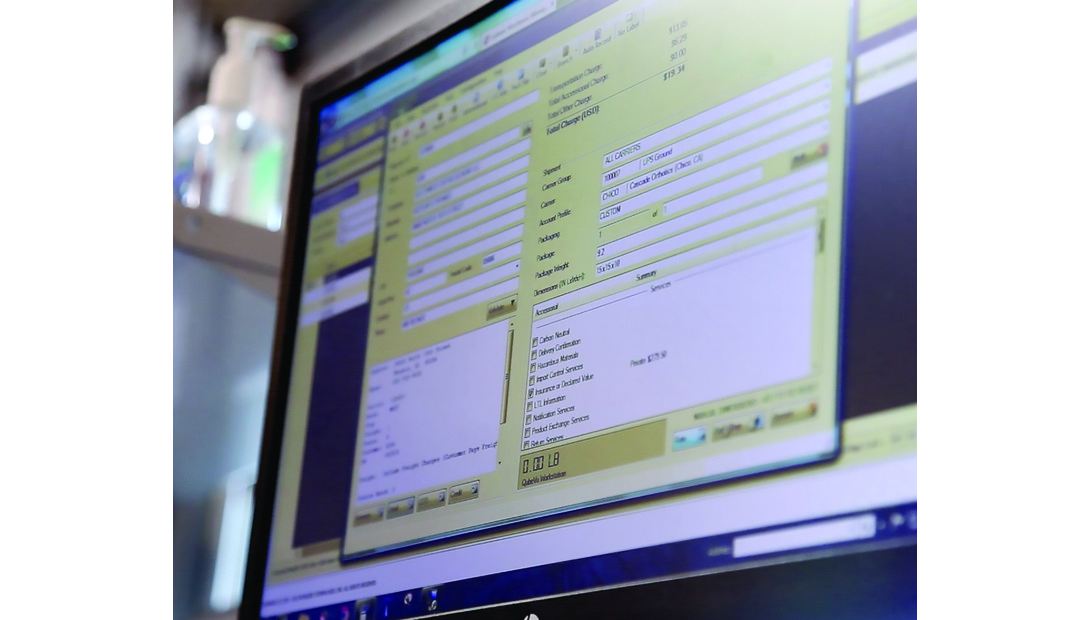

After exhaustively researching available options, Cascade became convinced that it would have to implement something new to achieve the company’s goals: an integrated combination of PathGuide’s Latitude Warehouse Management Manifest and Shipping System and Postea’s QubeVu Dimensioning Solution.

This implementation didn’t disappoint. It presented modern, fast, scanning technology at an affordable price. And that wasn’t the only benefit. Collins explains, “A secondary issue was the lack of integration with our warehouse management system and ERP systems. QubeVU’s API, along with their willingness to work with our developers, allowed us to take advantage of the technology AND have it integrate with our operating systems.”

The Results

As is often the case with large projects like this, the time and effort Cascade put into this research and eventual implementation has paid off big. Some of the most significant quantitative outcomes the company has experienced are:

--More precise shipping quotes during the order entry process has resulted in a more effective customer service experience. This has helped with customer retention and loyalty and increasing Cascade’s footprint within the existing customer base.

--Having highly accurate data in hand to use when deciding what carrier and service level to use for each outbound shipment has resulted in a net reduction of shipping costs per unit of sales. Furthermore, Collins notes that while Cascade ships primarily with one vendor, due to volume rebates that are available with consolidating the company’s shipments, one significant outcome of this implementation is that Cascade is now able to negotiate better pricing once they had more detailed information regarding the types of packages the company was shipping.

--Increased flexibility at the shipping station itself has resulted in a net increase in the amount of shipments that can be manifested in a given shipping day, which means nearly every order that makes it into the ERP system prior to order cutoff times now goes out same-day.

Additionally, Collins is looking forward to the opportunities this implementation will bring in terms of the availability of SKU dimensional information. “SKU dimensional information opens the doors to a host of other operational and value add services,” he elaborates. “Want to do warehouse automation? Need dimensions. Want to quote shipping charges on your website? Need dimensions. Want to work on inventory slotting? Need dimensions. This information is critical for advancing operations and working at best in class.”

Feel like these changes are something to implement in your organization? Will Crosby at Postea shares his top tip. “First and foremost: Get started on dimensioning today. Install dimensioning capability on every incoming/outgoing portal and start collecting that data in a WMS that is designed for it. The more data you collect, the better off you'll be when it's time to plan, choose a carrier mix, and negotiate contracts.”

A Clear Winner

When selecting the winner of the Game-Changer of the Year Award, we received many great submissions, but Cascade demonstrated that it truly was a game-changer. The organization went above and beyond simply trying to reduce shipping costs. Instead, cost reduction was only one aspect of their goals. Their desire to capture all the data available and use it to improve their bottom line, their understanding of their shipment profile, and the customer experience made them a clear winner, in our eyes. And we were proud to present Darryn Diamond, who accepted the award for his entire organization, with the PARCEL Forum Game-Changer of the Year Award, which was presented at a luncheon sponsored by Spend Management Experts.

Think your organization could be a game-changer? Stay tuned; we’ll be sending out submission forms for the 2017 award within the next couple of months! And we look forward to presenting another worthy company with this award at the 2017 PARCEL Forum, September 18-20, in Nashville!

An Overview of Cascade

• Largest independently-owned prosthetics and orthotics distributor in the United States

• 300 vendors with more than quarter of a million SKUs

• Five fully-stocked distribution centers with between four and six shippers per facility

• 97% same-day shipping record

• Acknowledged as a forward-looking organization at the forefront of technology, with a strong and ongoing commitment to excellence

![GettyImages-1288486122-[Converted]](https://cms-static.wehaacdn.com/parcelindustry-com/images/GettyImages-1288486122--Converted-.1781.widea.0.jpg)